Manufacturing & Assembly Services

Scale production, maintain quality, deliver products on time.

Efficiently and cost-effectively assemble products

Product Assembly Services involve the process of putting together various components to create a finished product. These services are utilized across numerous industries such as electronics, automotive, furniture, toys, appliances, and more. Companies often outsource assembly services to specialized providers to improve efficiency, reduce costs, and focus on their core competencies.

Product Assembly Services are an important part of the manufacturing process, providing businesses with the ability to efficiently and cost-effectively assemble their products. By leveraging specialized skills, advanced machinery, and efficient processes, these services can help businesses scale their production, maintain quality, and deliver their products on time.

Here is a breakdown of our full service offering

-

Manual Assembly

This type of assembly requires human labor to put together components. Manual assembly is suitable for small-scale production, complex assemblies, or products that require a high level of precision and care.

-

Automated Assembly

Automated assembly involves the use of machinery or robotics to assemble products. This method is often used for large-scale production and for products with a high degree of uniformity.

-

Mixed Model Assembly

In this setup, different models of a product are assembled on the same production line. This requires a highly flexible production process and is often used in industries like automotive, where different models of a car may be produced on the same line.

-

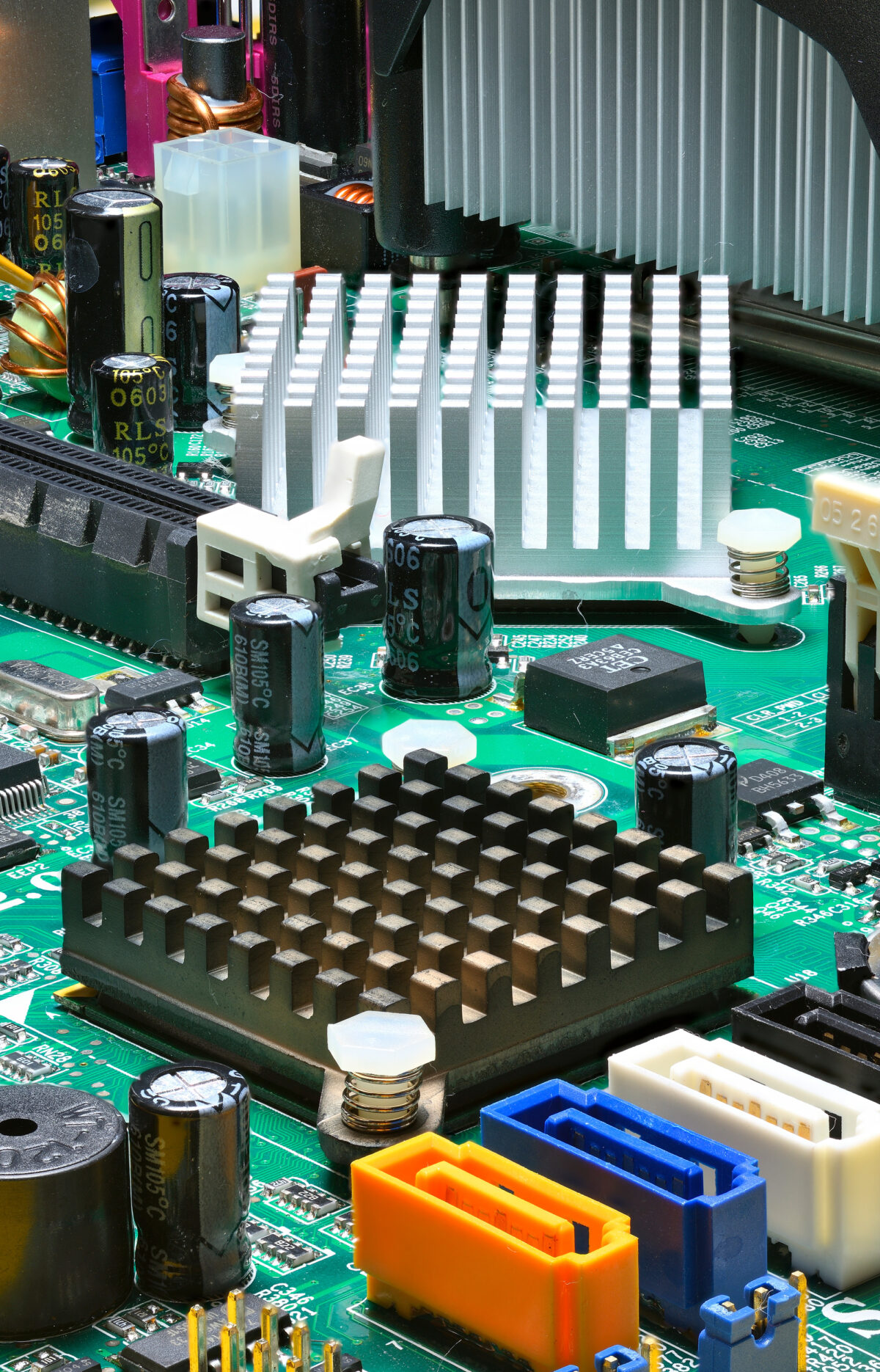

Electronics Assembly

This includes services like PCB (Printed Circuit Board) assembly, where electronic components are soldered onto a PCB, and system-level assembly, where various electronic subsystems are assembled into a complete product.

-

Mechanical Assembly

This involves the assembly of mechanical components into a finished product, such as assembling parts of a bicycle or an appliance.

-

Quality Control

Assembly services often include quality control measures to ensure that the assembled product meets the required standards. This can involve visual inspection, functional testing, and other QC methods.

-

Packaging and Fulfillment

After assembly, products are usually packaged and prepared for shipping. Some assembly service providers may also offer fulfillment services, where they manage inventory and ship products directly to customers.

-

Post-Production Support

This could include warranty service, repairs, or part replacement. Some providers may also offer support for product returns and recycling.

We create finished products

Leveraging specialized skills, advanced machinery, and efficient processes.