Electro-Optical Prototyping

Developing innovative solutions.

Using electronics to generate, control, and detect light.

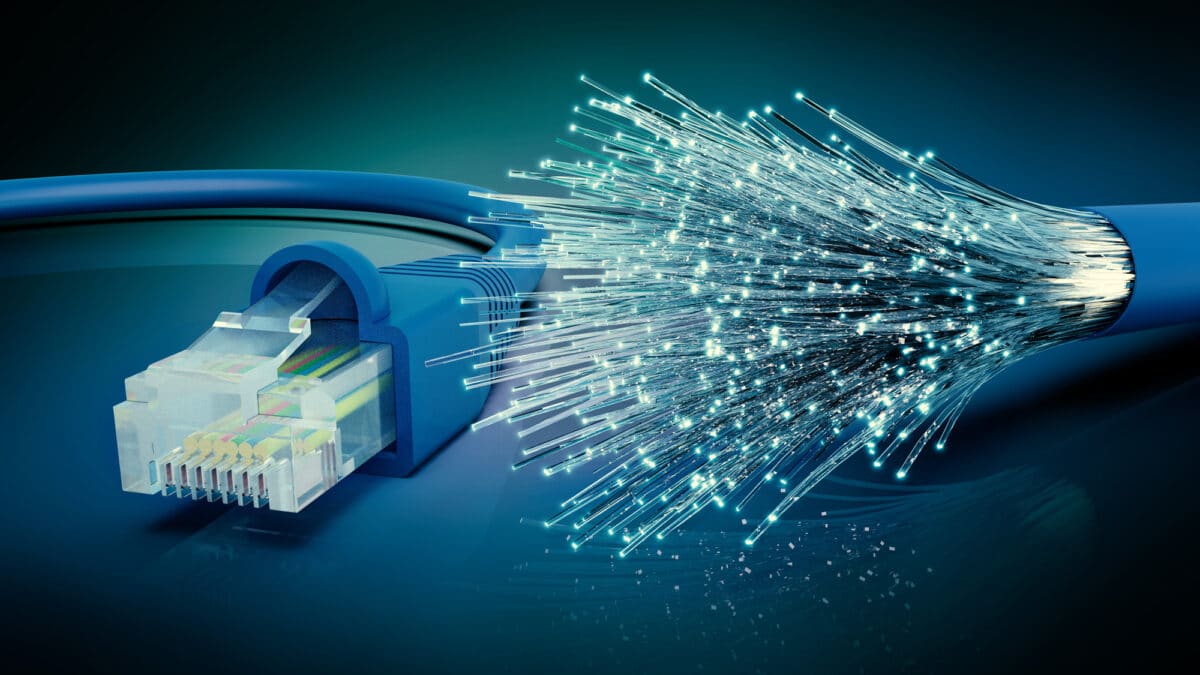

Electro-optical prototyping is the process of creating a physical model or sample (a prototype) of a device or system that uses both electronics and optics. Electro-optical systems include devices such as cameras, laser systems, night vision equipment, fiber optic communication systems, sensors, and more. These systems use electronics to generate, control, and detect light (optics), and vice versa.

Here is a breakdown of our full service offering

-

Design and Simulation

The process begins with a detailed design of the electro-optical system based on the intended application. Computer-aided design (CAD) and simulation tools are often used to optimize the design and predict the system's behavior.

-

Component Selection

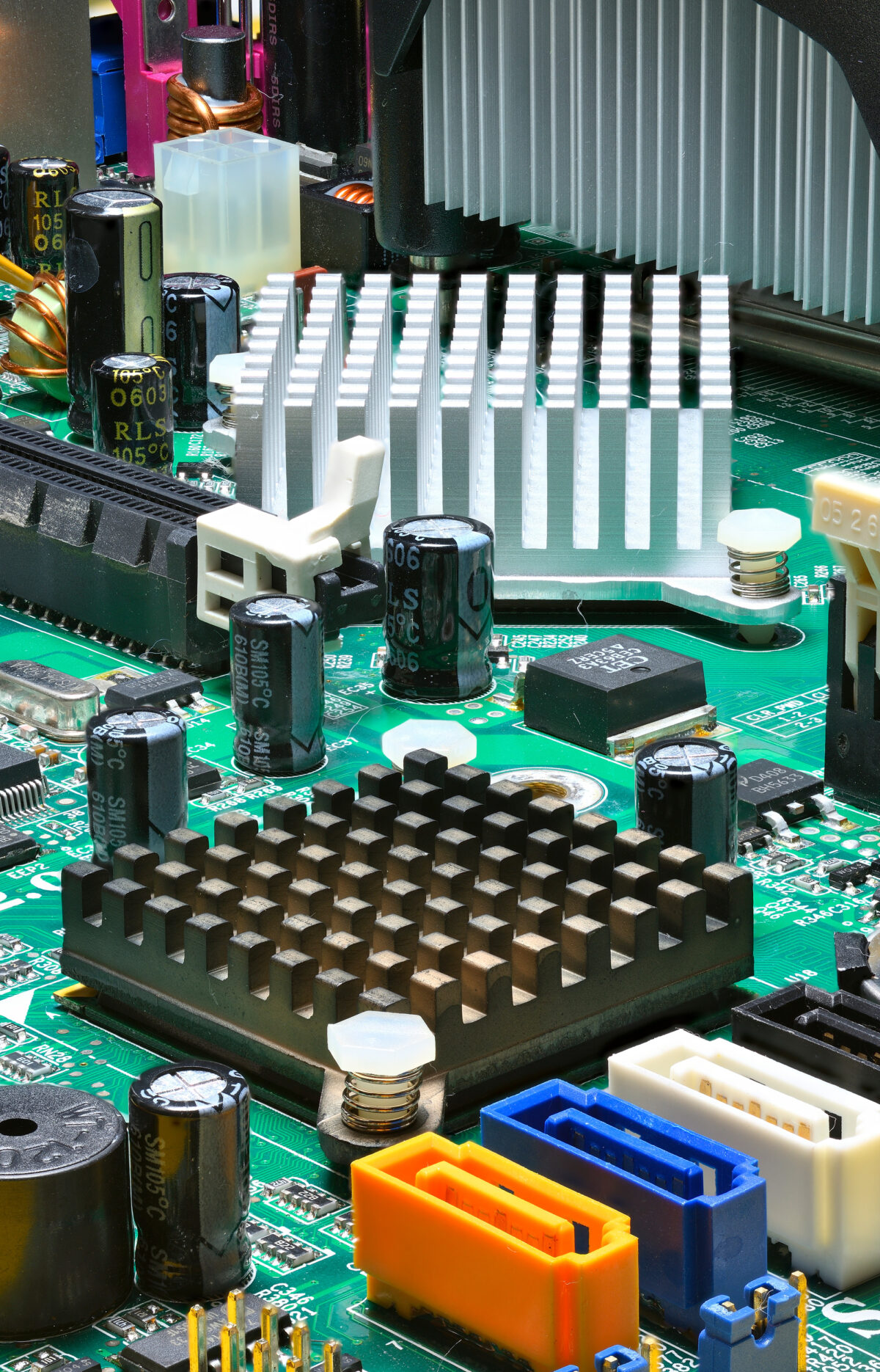

Appropriate electronic and optical components need to be selected based on the system's requirements. This can include items like lasers, photodiodes, lenses, mirrors, circuit components, and more.

-

Prototype Assembly

Once the design is finalized and components are selected, the prototype is assembled. This process requires precision and care to ensure that all components are properly aligned and connected.

-

Testing and Validation

The assembled prototype undergoes a series of tests to validate its performance, reliability, and safety. This may involve measurements of light output, wavelength, efficiency, response time, power consumption, and more.

-

Iterative Refinement

Based on the results of testing and validation, modifications may be made to the design or assembly process to address any identified issues or improve performance. This process of building and refining is often iterative.

-

Documentation and Review

All design decisions, assembly processes, and test results are thoroughly documented. This documentation is crucial for troubleshooting, future product improvements, and compliance with industry standards or regulations.

-

Scaling to Production

Once the prototype meets all requirements, the process can be scaled up to full production. This involves designing and setting up manufacturing processes that can produce the electro-optical system in larger quantities while maintaining the same performance and quality.

Our multidisciplinary approach combines electronics, optics, and mechanical engineering

Creating functional and reliable systems that can be produced in a cost-effective and efficient manner.